Stacked Slices Model Progress 2

I decided to change my concept to something that better utilized the stacked slices. Initially, I looked on google images for "stacked slices" and found that most of the results featured laser cut wood animals or else pictures of bread. I wanted to embrace grasshopper's functions, particularly the rotate and random function, so I decided to make a tree that had branches I could rearrange or rotate. I also had the idea of creating a mountain or another nature scene, but I felt that creating a topography was uninspired.

I thought about stacking the tree trunk the same direction as the branches, but using the laser cutter to create stacked circles both felt bland, but also felt like it was pointless as the cuts would ultimately be less noticeable. I might as well of bought a thick dowel and trimmed it. To make the rotation on the above animation, the steps on the range were set to 18 to create 19 outputs and the geometry was flattened so that the rotation would be applied to every individual ring of branches.

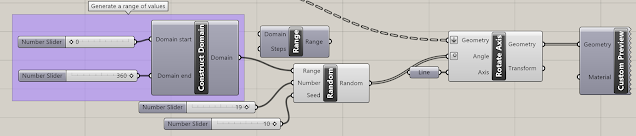

Using the random function, I found that I was also able to take each ring of branches and rotate each one individually. This took a lot of trial and error, as I found that the random feature would often apply the same angle change to every single piece. (I did the testing for this before I did the regular rotation animation seen above). Initially, I tried using range between the construct domain and random but I found that no matter what I changed the steps to, each random would be a specific segment of angles. For example, using 18 steps (gave me 19 outputs for my 19 branch layers) would create a range of 0-20 degrees, 21-40, etc. While this is still random I found that it created a more subtle random than I was hoping for, so I directly connected my construct domain (0 - 360 degrees) to the random feature. Seed was the slider I used for the animation and number was the number of slices I had. I found that the animation was choppy and felt less like a gif, so I also animated the trunk through the distance slider (material thickness) to create a consistency for reference. Of course, the rotate axis geometry had to be flattened or else all the branches would collectively be rotated 19 times and overlap to create a weirdly spikey star.

These are my grasshopper definitions for both the trunk and the tree top. The main difference is that the direction for the branches was set to z and the direction for the trunk was set to y.

For final printing, I am considering filleting the triangles to be more curved to lend a softer look to the overall tree. It would end up looking something like this:

.gif)

.gif)

Comments

Post a Comment